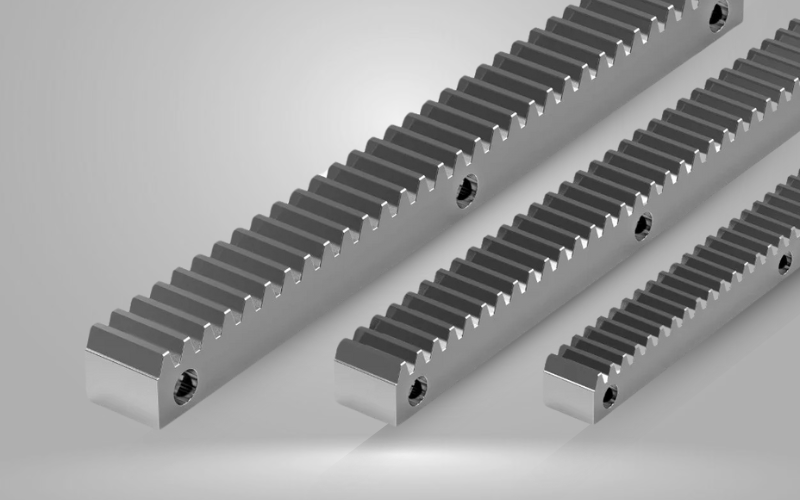

Guideway racks play an integral role in ensuring precision, durability, and efficiency in various industrial applications. Whether in automation, manufacturing, or heavy-duty operations, the reliability of guideway racks can significantly influence the performance of machinery. This article dives into the essentials of guideway racks, their types, applications, and why they are indispensable for modern industries.

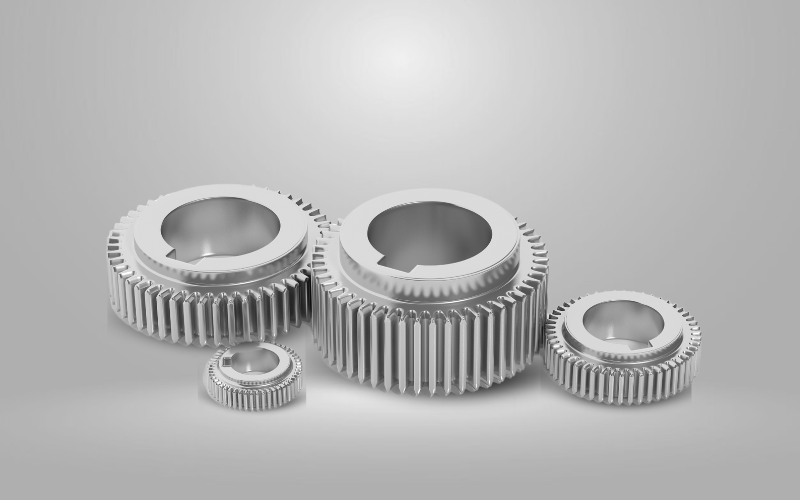

Guideway racks are specialized linear components designed for precision movement in industrial and mechanical systems. These racks are typically used in applications requiring accurate positioning, stability, and robust support. Manufactured using high-grade materials and advanced techniques, guideway racks are engineered to meet the demands of today’s high-performance machinery.

Key Features of Guideway Racks

- High Precision: Designed to ensure smooth and accurate linear motion.

- Durability: Built with high-quality materials to withstand heavy loads and prolonged use.

- Customization: Available in various specifications to suit diverse industrial needs.

- Low Maintenance: Designed for long-term use with minimal upkeep requirements.

Types of Guideway Racks

- Straight Guideway Racks: Ideal for applications requiring straightforward linear motion.

- Helical Guideway Racks: Engineered for high load capacity and smoother motion.

- Ground Guideway Racks: Perfect for high-precision tasks, offering exceptional accuracy.

- V-Type Milled Guideway Racks: Designed for stability and consistency in performance.

- Custom Guideway Racks: Tailored to meet specific industrial requirements.

Applications of Guideway Racks

Guideway racks are widely used across various industries due to their versatility and efficiency. Some key applications include:

- Automation: For precise motion in automated machinery and robotics.

- Manufacturing: To ensure accurate positioning in assembly lines and CNC machines.

- Heavy Machinery: Used in equipment requiring high load-bearing capabilities.

- Aerospace and Defence: For systems demanding extreme precision and reliability.

- Logistics and Warehousing: Essential for automated material handling systems.

Benefits of Using High-Quality Guideway Racks

- Improved Efficiency: Enhances the overall performance of machinery.

- Cost-Effectiveness: Durable construction minimizes replacement and maintenance costs.

- Versatility: Suitable for a wide range of applications across different industries.

- Enhanced Productivity: Precision motion reduces downtime and increases output.

Why Choose the Right Guideway Racks?

Selecting the right guideway rack for your application is crucial. The wrong choice can lead to inefficiency, increased wear and tear, and compromised machine performance. Always consider factors like load capacity, material, design, and application requirements before making a decision.

Conclusion

Guideway racks are indispensable components in today’s industrial landscape. Their ability to deliver precision, durability, and efficiency makes them a vital part of various applications. Investing in high-quality guideway racks not only ensures optimal machinery performance but also contributes to long-term cost savings and operational success.